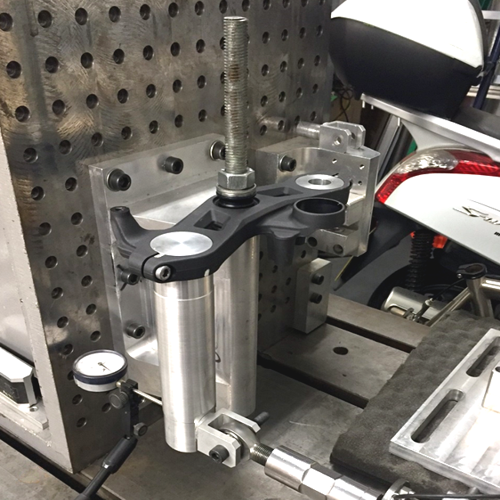

The Component

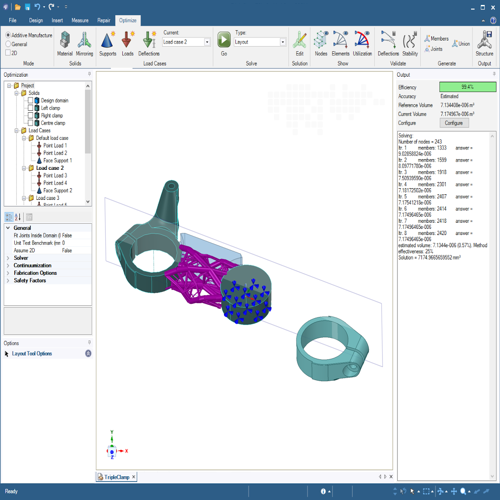

LimitState:FORM was used in the novel redesign of a top yoke component for world-leading motorcycle suspension engineers, K-Tech.

The optimized component was designed to match or better the strength and stiffness of the existing part, while also aiming to reduce the overall volume. After optimization stiffness was increased by an average factor of 1.65 in the three main loading directions, while the volume of material occupying the design space was reduced by over 60%.

“With LimitState:FORM we were able to reduce component mass while increasing the durability of the design.

The ability to quickly incorporate changes to our requirements and determine the effect this had on the design meant that development time was significantly shortened.”

A key advantage of LimitState:FORM is that it enables a more efficient workflow and, as a result, K-Tech benefited from being able to change design requirements fluidly throughout the project. For example, beam elements were extended, fillet radii added around all sharp edges and intersections and the design of one set of interfaces changed part-way through the project. These are exactly the kinds of design tweaks that engineers deal with on a day-to-day basis and LimitState:FORM made it easy for K-Tech to incorporate updates to their designs while still achieving excellent levels of optimization.

The Company

K-Tech Suspension is a specialist motorcycle suspension engineering company that drives competitive success in global road racing and motocross championships. They employ a dedicated R&D team who are constantly developing new and innovative products and run a training centre to ensure that all partners are fully trained and getting the most from the worlds leading suspension company.